Additive Manufacturing

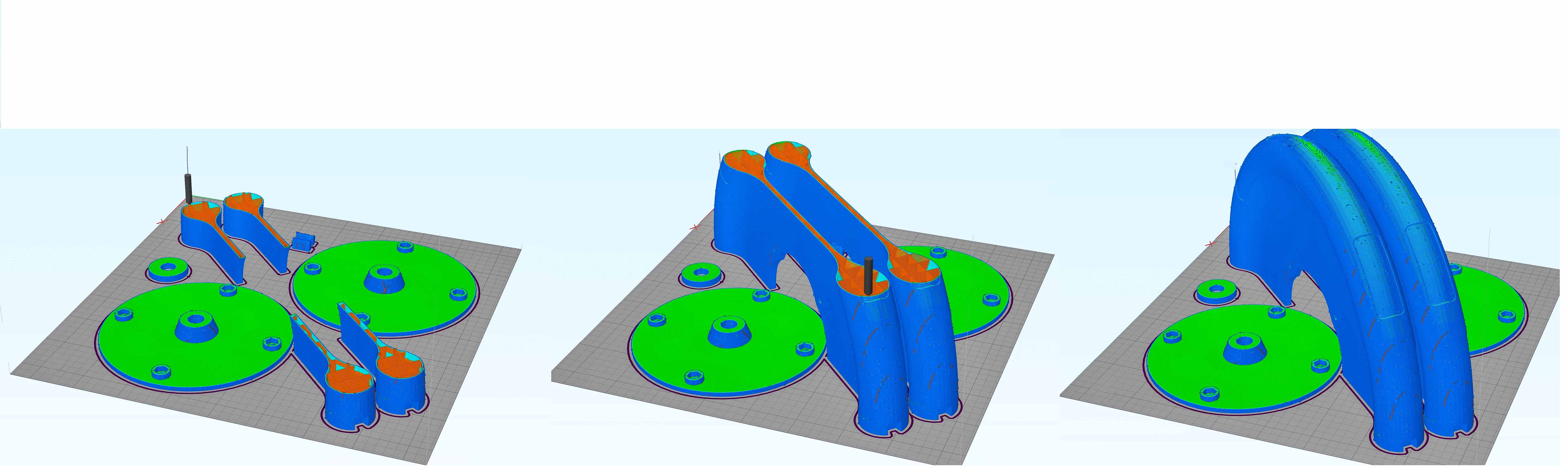

We extensively uses the Additive Manufacturing and 3D printing process in the production of our SAPRs. Contrary to what you can think of, we can get perfectly functional parts. The secret is a careful design and topological optimization phase that must take into account the characteristics of the production process used, which produces an anisotropic material. Indeed, by orienting the printing layers conveniently, resistive products are obtained similar to those obtained by injection molding. The most widely used material in our production is a co-polyester with a glass transition temperature of 81 ° C, with mechanical properties very similar to ABS.

We also provide third party design for Additive Manufacturing assistance and 3D printing services for parts and components, including an assessment of the feasibility and resistance of objects and the development of a suitable 3D printing process. In order to successfully produce functional components, the magnitude and direction of the stresses, the temperature of use and the assembly techniques must be evaluated. We are able to produce components with different filling densities during printing, in order to optimize weight.

To get a personalized quote, contact us!